Imagine trying to bake a cake where the person deciding on the ingredients (the recipe developer) never actually talks to the person buying them (the shopper), and neither of them really communicates with the person doing the actual baking. Sounds like a recipe for disaster, right? You’d end up with a mess, wasted ingredients, and a very confused baker.

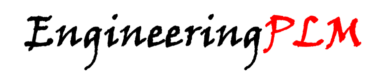

This, in a nutshell, has been the frustrating reality for countless manufacturers dealing with the infamous divide between their Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) systems. For too long, these two titans of enterprise software have operated in their own castles, guarding their respective data, leading to what we politely call “data silos.”

But in today’s fast-paced, complex manufacturing world, merely coexisting isn’t enough. It’s time for a proper conversation, a strong bridge to be built, to finally achieve that elusive “single source of truth” that everyone talks about.

Understanding the Divide: Two Sides of the Same Coin

Let’s quickly recap what each system does best:

PLM: The Brains of the Product

This is where innovation lives. PLM manages everything about the product itself: the design, the engineering specifications, CAD files, Bills of Material (BOMs), change orders (ECOs), compliance documents, and testing results. It’s all about what the product is, how it’s designed, and why it exists in its current form. It’s dynamic, iterative, and focused on development.

ERP: The Engine of the Business

This is where the business operations hum. ERP handles how the product is made and sold: procurement, inventory management, production planning, financial accounting, sales orders, and shipping. It’s about what resources are needed, when things should be produced, and how much it costs. It’s structured, transactional, and focused on execution.

See the problem? One focuses on the definition, the other on the execution. They’re intrinsically linked, yet often completely disconnected.

The Cost of the Chasm: Where Data Silos Hurt

When PLM and ERP aren’t truly integrated, it’s not just an inconvenience; it’s a direct hit to your bottom line and your ability to innovate.

- Manual Data Entry & Errors: This is the most common and soul-crushing problem. An engineer releases a new BOM in PLM, and someone in operations then has to manually re-enter that data into ERP. This is a breeding ground for typos, missed updates, and frustration. One wrong digit can lead to ordering thousands of the wrong part.

- Out-of-Sync BOMs: The Engineering BOM (EBOM) in PLM, which defines the product, often differs from the Manufacturing BOM (MBOM) in ERP, which specifies how it’s built. These discrepancies lead to production delays, rework, and wasted materials because manufacturing is working off outdated or incorrect information.

- Delayed Time-to-Market: Product launches slow to a crawl when design freezes in PLM can’t seamlessly translate into production planning in ERP. Every manual step adds days, sometimes weeks, to your schedule.

- Poor Cost Visibility: Engineers design for functionality and performance. Without real-time access to actual material costs, inventory levels, and production capacities from ERP, they might inadvertently design a product that’s incredibly expensive or difficult to manufacture.

- Compliance Headaches: Tracking the complete lineage of a product for regulatory compliance (think medical devices or aerospace) becomes a forensic expedition when data is fragmented across systems.

- Frustrated Teams: Your talented engineers and operations professionals didn’t sign up to be data entry clerks. The friction between departments due to conflicting information saps morale and productivity.

In essence, you have two versions of the truth, and everyone is trying to build your product from a different script. Chaos reigns.

Building the Bridge: Achieving the Single Source of Truth

The good news is that bridging this gap is no longer a pipe dream. Modern integration technologies and a strategic approach can turn this division into a unified powerhouse.

1. Define Clear Data Ownership & Master Data Management

This is the foundational step. You need to explicitly decide which system is the “master” for each piece of data:

- PLM owns: Product definitions, engineering BOMs (EBOMs), CAD files, specifications, revision control, engineering change orders (ECOs), and intellectual property.

- ERP owns: Manufacturing BOMs (MBOMs – derived from EBOMs), routing, supplier data, inventory, purchasing, production schedules, sales orders, and financial data.

This clarity prevents conflicts and ensures everyone knows where to go for the definitive answer.

2. Implement Robust Integration: Automated, Not Manual

This is where the technical magic happens. Forget manual re-entry. Modern integration platforms and APIs allow for automated, real-time (or near real-time) data synchronization. Key integration points include:

- BOM Synchronization: When an EBOM is released in PLM, it should automatically push relevant data to ERP to create or update the MBOM. This often involves a “transformation” process to adapt the engineering view to a manufacturing view (e.g., adding phantom assemblies, process steps).

- Part Number Management: New part numbers created in PLM should flow seamlessly to ERP for procurement and inventory.

- Change Management (ECO/ECR): An approved ECO in PLM should automatically trigger updates in ERP for affected BOMs, routings, or production schedules, ensuring manufacturing is always working with the latest design.

- Cost & Availability Feedback: While PLM owns design, it can consume cost and inventory data from ERP. This allows engineers to make “design for cost” decisions informed by real-world data, not just estimates.

3. Standardize Processes & Workflows: The Human Glue

Technology is only half the battle. Your teams need to agree on how they will work with the integrated systems. This means:

- Formalized Release Workflows: Clear gates and approvals for when design data is “ready” for manufacturing.

- Collaborative Change Management: Ensuring both engineering and operations can easily initiate and contribute to changes, with full visibility.

- Training & Adoption: Everyone involved needs to understand the new, integrated workflows and the tangible benefits it brings to their daily work.

The Payoff: A Unified Vision

When your PLM and ERP finally talk, you move beyond mere data exchange to true strategic alignment. The benefits are transformative:

- Faster Product Launches: Streamlined data flow drastically cuts time-to-market.

- Reduced Costs & Waste: Fewer errors, less rework, and optimized material usage.

- Improved Quality & Compliance: A single, traceable data set for every product, from concept to customer.

- Enhanced Collaboration: Engineering, manufacturing, supply chain, and finance all work from the same trusted information, fostering harmony and efficiency.

- Agility & Innovation: Respond faster to market changes, incorporate customer feedback, and accelerate your innovation cycles.

The “single source of truth” isn’t just a buzzword; it’s the operational backbone of a thriving, competitive manufacturing business. It’s time to build that bridge and bring your PLM and ERP into a truly collaborative, unified future.