Beyond the Digital File Cabinet: Why It’s Time to Trade PLM for Product Lifecycle Intelligence

For decades, Product Lifecycle Management (PLM) has been the backbone of the manufacturing world. It was the “single source of truth,” the digital file cabinet where CAD drawings, bills of materials (BOMs), and engineering changes went to live. If you knew where to look, you could find the history of a part from cradle to grave.

But let’s be honest: in today’s hyper-accelerated market, having a “source of truth” isn’t enough anymore. Truth, in a static database, is just history. What companies need now isn’t just a record of what happened; they need an understanding of what is happening and what will happen.

We are entering the era of Product Lifecycle Intelligence (PLI). The shift from PLM to PLI isn’t just a software upgrade; it’s a fundamental change in how we think about product data—from a passive record to an active, predictive engine.

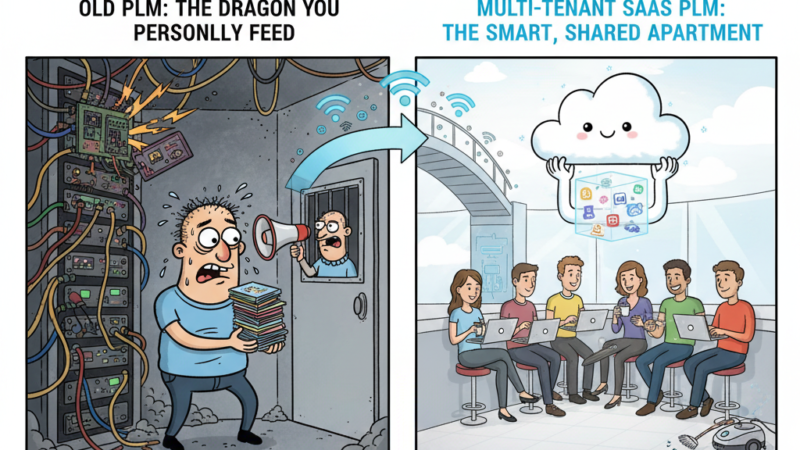

The PLM Ceiling: Why Traditional Systems are Stalling

Standard PLM systems were designed for a world that was linear and relatively predictable. You designed a product, sourced the materials, manufactured it, and shipped it. The PLM tracked the documentation at each stage.

However, the modern manufacturing environment is anything but linear. Supply chains are volatile, sustainability requirements are shifting by the week, and consumer demands change faster than a design cycle can keep up. Traditional PLM has hit a ceiling for three specific reasons:

Data Silos with Different Dialects: Even within a PLM, data often stays trapped. Engineering talks in geometry; Procurement talks in costs; Sustainability talks in carbon equivalents. PLM stores this data, but it doesn’t translate it.

The “Rear-View Mirror” Problem: Traditional PLM tells you what you decided six months ago. It doesn’t tell you that a specific resin you’ve specced is currently stuck in a port or that a new regulation in the EU will make your packaging illegal by the time the product hits the shelves.

Human Overload: We are generating more data than any human team can reasonably analyze. Expecting an engineer to manually cross-reference thousands of components against fluctuating market prices and environmental impact scores is a recipe for burnout and error.

What is Product Lifecycle Intelligence (PLI)?

If PLM is a map, PLI is a high-end GPS with real-time traffic updates, weather alerts, and predictive rerouting.

Product Lifecycle Intelligence is the integration of Artificial Intelligence (AI), Machine Learning (ML), and Big Data analytics into the product development process. It takes the foundational data found in PLM and layers on external feeds—market trends, supply chain logistics, IoT feedback from products in the field, and even social sentiment.

In a PLI environment, the system doesn’t just store the BOM; it analyzes it. It might flag a component and say, “This part has a 40% chance of a supply shortage in Q3. Here are three alternative materials that maintain the structural integrity and lower your carbon footprint by 12%.” That is the leap from management to intelligence.

The Three Pillars of the PLI Shift

To move from PLM to PLI, companies need to focus on three core transformations: Connectivity, Predictability, and Agility.

1. Connectivity: Breaking the “Digital Thread” Myth

We’ve talked about the “Digital Thread” for years, but in most companies, that thread is more like a series of knots. PLI requires a seamless flow of data not just within the company, but from the outside world. This means connecting your internal design data to live supplier inventories and global regulatory databases. When these systems talk to each other, the “intelligence” happens automatically.

2. Predictability: Moving from “What?” to “What If?”

The most powerful feature of PLI is simulation—not just physical simulation (like stress tests), but business simulation. PLI allows teams to run “What If” scenarios. If the price of aluminum spikes by 20%, how does that affect the margin of our entire 2026 portfolio? PLI provides these answers in seconds, allowing leaders to make proactive decisions rather than reactive ones.

3. Agility: Empowering the Edge

In a PLM world, changes are slow and bureaucratic. In a PLI world, data-driven insights are pushed to the people who need them most. An engineer gets an automated alert during the design phase if a chosen fastener is underperforming in the field based on IoT data from current products. This prevents “designing in” failures before they ever reach production.

The Sustainability Mandate

We cannot talk about the shift to PLI without talking about the planet. Sustainability is no longer a “nice to have” or a marketing slogan; it is a core business requirement.

Traditional PLM struggles with sustainability because carbon footprints are moving targets. The impact of a product changes based on where a part is sourced and how it is transported. PLI can calculate the “cradle-to-gate” impact in real-time. By the time a design is finalized, the team knows exactly what the environmental cost will be. This level of transparency is impossible with static lifecycle management.

Overcoming the “Cultural Inertia”

The biggest hurdle to PLI isn’t the technology—it’s the mindset. Many organizations have spent millions on their PLM implementations and are hesitant to “start over.”

The good news is that shifting to PLI doesn’t mean ripping and replacing your PLM. It means evolving it. It’s about layering intelligence on top of your existing data. It requires a culture where data is trusted, where AI is viewed as a co-pilot rather than a threat, and where cross-departmental collaboration is the default mode of operation.

The Competitive Edge: Why Now?

The gap between companies that use PLI and those that stick to traditional PLM is widening. Those with “Intelligence” are bringing products to market faster, with fewer recalls, higher margins, and better sustainability ratings. They aren’t smarter because they have better people; they are smarter because their data is working for them 24/7.

The transition from PLM to PLI is the move from being a historian of your products to being a conductor of their future. It’s time to stop just managing the lifecycle and start mastering it.

Bonus Content – Actionable Checklist: Transitioning from PLM to PLI

If you are ready to move beyond basic management and into the realm of intelligence, use this checklist to guide your organization’s transition.

Phase 1: Foundation & Audit

- [ ] Audit Data Quality: Does your current PLM contain “dirty” or incomplete data? Intelligence is only as good as the inputs. Clean up your naming conventions and part libraries.

- [ ] Identify Data Silos: Map out where product data lives outside the PLM (Excel sheets, local drives, email).

- [ ] Assess Integration Readiness: Check if your current PLM has robust APIs to connect with external data sources (ERP, CRM, IoT, and Supplier Portals).

Phase 2: Integration & Connectivity

- [ ] Establish a Digital Thread: Ensure that data flows bi-directionally between Engineering, Manufacturing, and Service.

- [ ] Connect External Feeds: Integrate real-time market data, such as commodity pricing, regulatory updates (e.g., REACH/RoHS), and supply chain risk indices.

- [ ] Implement IoT Feedback Loops: Create a pathway for performance data from products in the field to be fed back into the engineering design environment.

Phase 3: Intelligence & Analytics

- [ ] Deploy AI/ML Layers: Invest in analytics tools that sit on top of your PLM to identify patterns, such as common failure points or over-engineered components.

- [ ] Enable Predictive Simulation: Move beyond CAD/CAE to business-level simulations (Cost-to-Design, Carbon-to-Design).

- [ ] Automate Routine Decisions: Set up “smart triggers”—for example, automated alerts when a specified part reaches a certain “end-of-life” risk level.

Phase 4: Culture & Strategy

- [ ] Redefine Roles: Train engineers and product managers to interpret data-driven insights rather than just performing data entry.

- [ ] Establish Data Governance: Appoint “data stewards” responsible for the health and accessibility of the product intelligence stream.

- [ ] Measure “Time-to-Insight”: Shift your KPIs from “Time-to-Market” to “Time-to-Insight”—how fast can your team react to a market change?

The shift to PLI is a journey, not a destination. By checking these boxes, you’re not just managing a product; you’re building a smarter, more resilient business.